Basic & Fire Awareness Course

This course provides the skills and confidence that will allow staff to carry out their duties relating to fire safety and emergency procedures.

Who should attend

All staff

Basic & Fire Awareness Course

At the end of the course the student will:

- Be aware of the dangers of fire

- Understand the nature of fire and how it spreads

- Be aware of simple fire prevention measures

- Understand what to do in the event of a fire alarm

- Be able to distinguish between different types of fire extinguishers

- Be able to tackle small fires safely and effectively

- Be equipped to perform their fire safety duties

Content

- Basic fire prevention

- Evacuation

- Chemistry of combustion

- Practical ‘first-aid’ firefighting on live fires

Certificate

A certificate is provided confirming attendance

Fire Hydrant Testing

Fire hydrants are installed primarily for use by the Fire & Rescue Service (FRS) to rapidly secure a water supply to extinguish a fire in the vicinity. Fire hydrants may also be installed for other purposes that allow a water supplier access to the pressurised water network.

The water supplier is responsible for installing and maintaining fire hydrants that are in the public domain. This is done on behalf of the FRS. Private fire hydrants can be installed by water suppliers or private companies and the responsibility for maintenance and testing lies with the site owner, occupier or operator. Examples of private sites would be universities, hospitals, retail parks and distribution centres.

Fire hydrants, private or public need to be maintained so that they will be ready for use and readily accessible by the FRS. The installation and maintenance should be carried out in accordance with BS 750-2012. The maintenance and testing should be carried out annually and should include the following:

- Inspection of

- Cover and frame

- Surrounding area

- Pit and valve

- Indicator plate

- Flow test

- Static pressure test

All work carried out by Abbey Fire (UK) Ltd is followed up by individual hydrant reports and test/compliance certificates. Should any remedial work be required a quote will be submitted with the certification.

We carry out Fire Hydrant maintenance nationally and to all types of installation. Should you require further information our highly experienced team of ex firefighters would be pleased to talk to you.

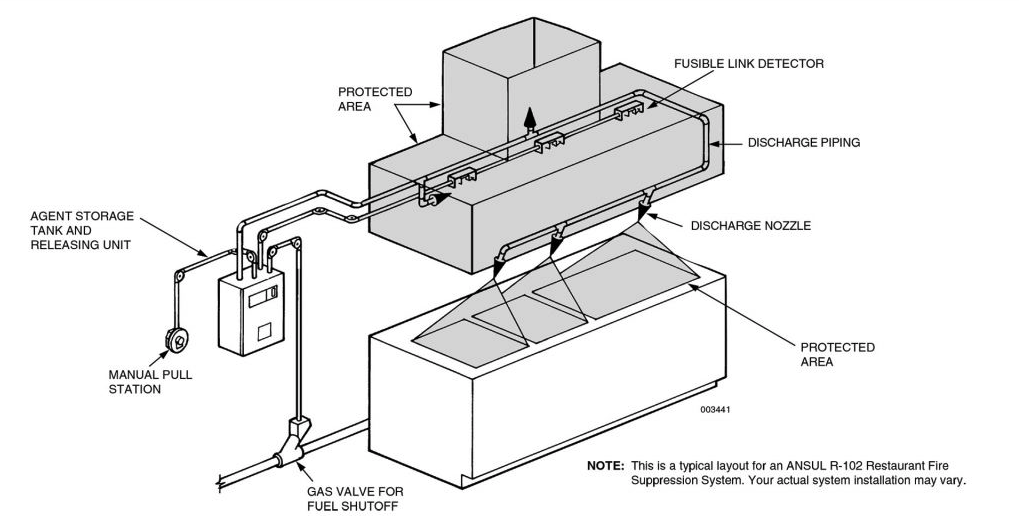

Kitchen Fire Suppression System

We are an approved supplier of the Ansul R102 Kitchen Fire Suppression System.

ANSUL products protect more food service kitchens from fire than any other brand. The R102 Fire Suppression System incorporates a flexible design with an extremely effective ANSULEX Low pH Liquid Agent. ANSULEX quickly knocks down flames and cools hot surfaces, while generating a tough vapor securing blanket that helps prevent re-flash.

The R102 system is designed to protect areas associated with ventilating equipment, including hoods, ducts, plenums, and filters. It also protects auxiliary grease extraction equipment and cooking equipment such as various types of fryers, griddles, range tops, broilers, char-broilers and woks. The system is ideally suited for commercial kitchens in fast food chains, retail food courts, diners, convenience stores, catering facilities, mobile food trucks, hotels and casinos, stadiums, schools, hospitals and more.

The R102 system is cooking equipment friendly and offered in two designs: Appliance-Specific and Overlapping. The appliance-specific design aims the nozzles at the specific hazard areas of each appliance. With the overlapping design, the nozzles are arranged to overlap and provide a “fire-free zone” throughout a group of appliances.

Ansul R102 Suppression systems are to be serviced on a bi-annual basis.

When an Ansul R102 Suppression system is installed, it will immediately offer protection to staff, premises & equipment. After 6 months, the bi-annual service will be required. This ensures you are meeting the system requirements and, subsequently, ensures you are conforming to your insurance providers requirements.

The service comprises of a full inspection and test to ensure it still has the capability to fire. In addition to ensuring the system will fire, the engineer will also look at whether the system is still covering the appropriate risks. Upon completion of the service, a report will be produced specifying whether the system is appropriate for the risks or whether further works are required.

10 year tests are a legal requirement of the system. Once the system reaches 10 years old, it must be given an overhaul. This is a specific requirement to comply with British standards. If this requirement is not satisfied, the system may not work when required to do so or, even worse, cause an injury to someone when the system is fired.

Please feel free to contact a member of our team to discuss the different service options we have on offer.